Wood Plastic Board

- PREMIUM

- Jinan City, Shandong Province

- 3-5days

- 2000tons per month

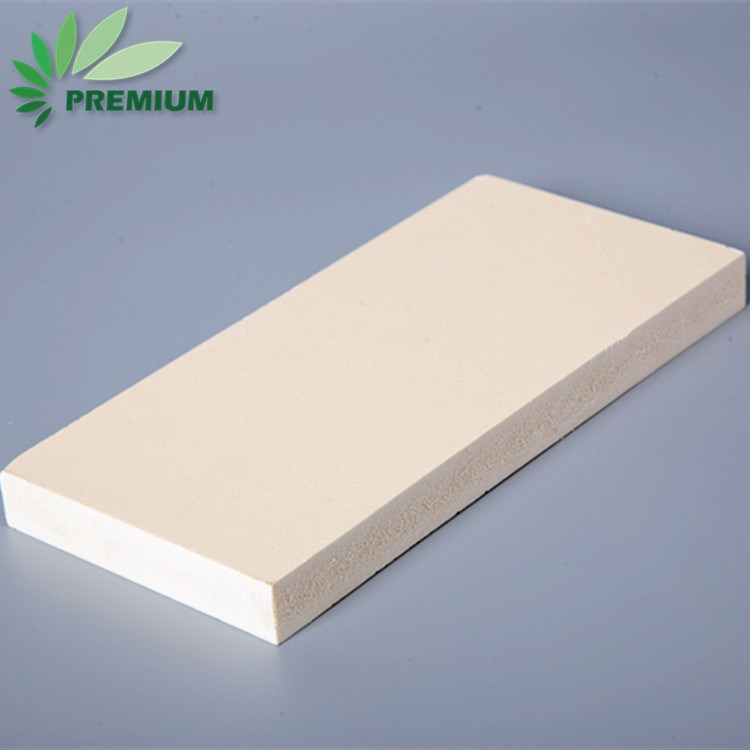

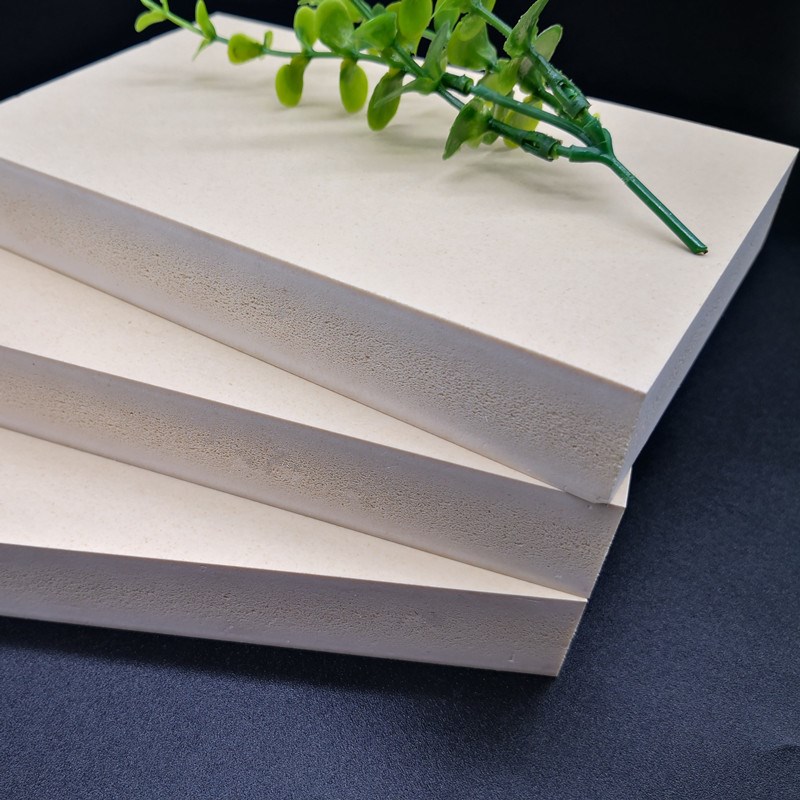

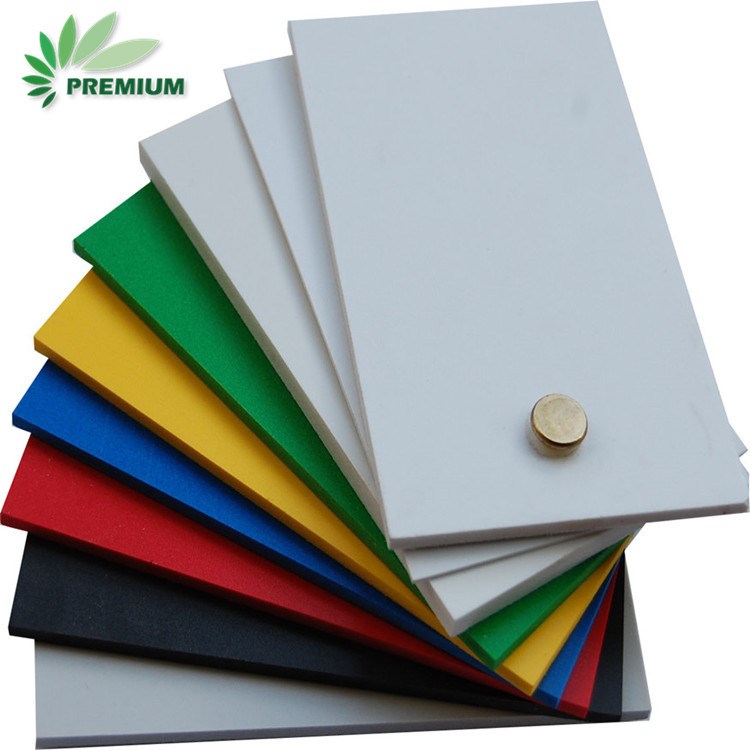

1. Wood Plastic Board: wood plastic composite, short for WPC.

2. Anti uv, sound insulation, thermal insulation,waterproof, anti-deformation, acid and alkali resistant, fire-retardant, anti-corrosion,anti-mildew and anti-pest, moisture resistance etc.

3. Good hardness, surface smooth and glossy. Ideal material used for door making, furniture making.

Wood Plastic Board

Anti-UV

Sound Insulation

Thermal Insulation

Waterproof

Anti-Deformation

Acid And Alkali Resistant

Fire-Retardant

Anti-Corrosion And Anti-Mildew

Anti-Pest

Moisture Resistance

Wood plastic board(wpc board) Application:

Sheet 1:

Transportation shipping industry: Internal decoration board of plane, train, bus, roof of wing-room,etc. |

Architecture industry and decoration industry: Building outdoor wall board, indoor decoration board,partition board in office and house, etc. |

Advertising: Screen sheet printing, laser engraving and billboard |

Industry: Chemical anticorrosion project, refrigerator sheet, special cold project,environmental protection |

Others: Moulding board, sports equipments, seashore moisture-proof facility, water resistant material, art designing material and etc |

Sheet 2:

1. No harmful components of environment |

2. Waterproof, acid and alkali resistant |

3. Process ability is superior to wood. |

4.Artistic and natural beauty |

Sheet 3:

Project | Index |

Elongation at break(MPa) | ≥10 |

Schauder hardness D | ≥55 |

Impact strength of free beam(kj/m2) | ≥13 |

Heating size change ratio(%) | ≥10 |

Variance ratio of heating size(%) | ±2.0 |

Softening point(°C) | ≥70 |

Bending strength(MPa) | ≥21 |

Bending elasticity ratio(MPa) | ≥600 |

Strength of holding screw(N) | ≥800 |

Water absorption(%) | ≤1.0 |

Surface density(kg/m3) | ≤800 |